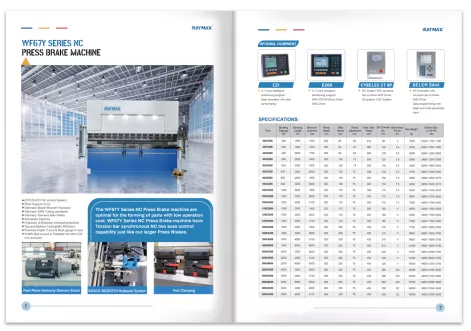

- Hydraulic guillotine shearing machine adopts all EU streamlined design, manufactured with welding robot and stress relieving process.

- Guillotine shear cutter is easy to maintain and more reliable with integrated hydraulic system, hydraulic system from Bosch Rexroth, Germany.

- RAYMAX hydraulic shear has variable bevel action to adjust cutting length and load capacity according to different needs.

4.The guillotine metal shear backgauge distance is adjusted by motor and displayed by ELGO P40T servo motor. - Automatic shearing machine is equipped with light alignment function for alignment during shearing and stepless knife beam stroke adjustment.

- CNC hydraulic shearing machine is equipped with safety fence and electrical interlock, which complies with CE standards and ensures hydraulic metal shear safe operation.

RAYMAX

Guillotine Shearing Machine

Feature

Tags:

PRODUCT DETAILS

Introduction of Raymax's Guillotine Shears

The frame structure of the guillotine shearing machine adopts all-steel welding; the four-cornered and eight-sided right-angle guide rails have high precision, good rigidity and hydraulic preload.

The hydraulic system of guillotine shears adopts two-way plug-in integrated valve, and can be equipped with stroke digital display, photoelectric protection device and mobile workbench.

The shearing machine has double-action function of upper slider and lower hydraulic pad, and the working pressure stroke can be pressed within the specified range.

The sheet shearing machine process requires adjustment, and the operation is simple and centralized using buttons.

Difference between swing beam shearing machine and guillotine shearing machine

1. The shearing principle is different: the swing beam shearing machine uses the oscillating motion of the mechanical swing arm to complete the shearing action under the action of inertia; The guillotine shearing machine, on the other hand, uses a clamping knife holder controlled by a hydraulic system to complete the shearing action under the action of the blade.

2. Different processing ranges: swing beam shear machines are suitable for processing thinner materials, while guillotine type shearing machines are suitable for processing thicker materials.

3. Different cutting speeds: The swing shearing machine has a faster cutting speed and higher production efficiency; The guillotine shearing machine has a slower cutting speed but a stronger cutting force.