- Swing beam shearing machine adopts steel plate welding structure, hydraulic transmission, accumulator return, easy operation, reliable performance, and beautiful appearance.

- The adjustment of the cnc shearing machine blade gap is indicated by a signboard, making it easy and quick to adjust.

- CNC metal shears use a fence style personal safety protection device.

With plate shearing machine, there is a digital display device for the size and cutting frequency of the rear stopper material. - Metal shear machine with hydraulic transmission, swinging tool holder; Hydraulic metal shear adopts hydraulic integrated valve blocks from Bosch Rexroth, the compact structure reduces pipeline connections and improves system reliability and maintainability.

- The overall welding of the hydraulic swing beam shearing machine frame is sturdy and durable, and the use of an accumulator oil cylinder for smooth and rapid return travel.

- Hydraulic shearing machine has the function of infinitely adjusting the stroke, and the gap between the upper and lower blade edges can be adjusted with a handle, making shearing machine easy to adjust the uniformity of the blade gap.

- The swing beam CNC shearing machine adopts an all steel welding structure, which eliminates stress through vibration and has good rigidity and stability. CNC shearing machine protective barriers and electrical interlocking ensure safe operation.

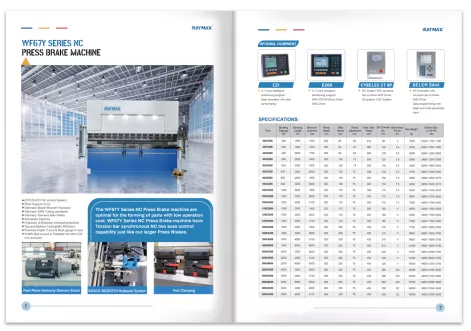

RAYMAX

Hydraulic Swing Beam Shearing Machine

Features

Tags:

PRODUCT DETAILS

Introduction of Raymax's Swing Beam shearing machine

Swing Beam shearing machine is a common mechanical shearing equipment, characterized by fast cutting speed, low noise, smooth cutting, narrow cutting seam, suitable for processing thinner plates and thin-walled pipes. Hydraulic swing beam shearing machine’s working principle is to quickly "cut" the material through the tool on the mechanical swing arm, so it is also known as "swing arm shear" or "mechanical shear".

The structure of a swing beam shearing machine generally consists of a body, a shearing mechanism, a transmission mechanism, and a control system. Among them, the swing arm shearing mechanism is its core component and the biggest difference from the gate type shearing machine. The swing arm shear mechanism generally consists of two symmetrical shear cutting tools, shear arms, shear shafts, shear bolts, and other parts. By swinging the cutting arm, the cutting tool is driven to perform a cutting action, completing the cutting of the workpiece.