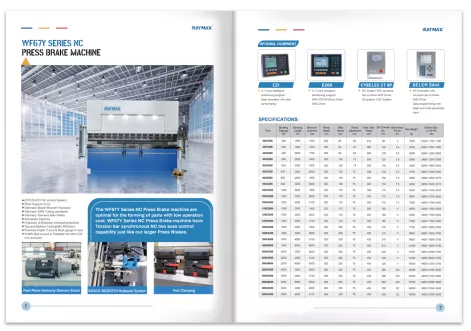

- High precision: Cutting accuracy up to 0.1mm

- High efficiency: Cutting speed up to 20m/min

- Durable: Adopt high-quality materials, compact structure, durability, long service life, can be used for a long time

- Lowcost: High cutting quality, high surface finish, no need for post-processing, can greatly save processing costs.

- Energy saving

- Environmental protection

RAYMAX

RX-4020H 12000KW Fiber Laser Cutting Machine

Features

Tags: