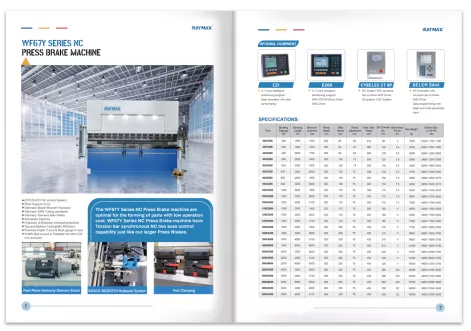

- The NC press brake machine can be configured with various models of dedicated CNC systems: E21, E310, CT8, etc.

- NC press brake is equipped with multi-step programming function, it can achieve automatic operation and continuous positioning of multi-step programs, and automatically adjust the position of backgauge and slider;

- Bending counting, real-time display of processing quantity, memory of the position, program, and parameters of the material blocking slider after power outage;

- The press brake bending machine backgauge adopts imported ball screws and linear guides, ensuring the positioning accuracy of the backgauge and higher machining accuracy.

- The sheet metal bending machine adopts torsion bar synchronization and mechanical blocking, reliable, economical, and high precision.

- The distance between the backgauge and the stroke of the upper slider are automatically adjusted by the CNC system, and can also be manually adjusted for easy operation.

RAYMAX

RX-N Series NC Press Brake with E21 2 Axis

Features

Tags:

PRODUCT DETAILS

Torsion Bar Press Brake Bending Machine Components

The torsion bar press brake bending machine is mainly composed of frame, torsion bar, motor, transmission system, positioning device and clamp. The frame is the supporting framework of the whole machine, the torsion bar is the core component, the motor and transmission system provide the power, the positioning device and clamp are used to fix the plate and clamp the plate respectively.

Working Principle of NC Press Brake Machine

NC press brake machine is used to achieve the bending process of sheet metal through the rotation of the twist axis. A torsion bar generally consists of two curved shafts, one of which is fixed with a clamp, and the sheet metal is fixed on the clamp. When the motor drives the transmission system to work, the torsion bar starts to rotate, and the clamp on the bar will also rotate together, so that the sheet metal is subjected to centrifugal force during rotation, achieving the bending of the sheet metal. NC bending machine is controlled by the programme, so that the bending work coordinate point moves along the X-axis and Y-axis, so that the processed parts are bent and deformed.