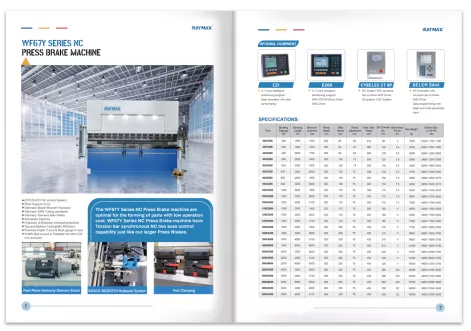

- The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

- Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

- Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

- 4.The stroke of cylinder (Y1,Y2 ) and back gauge ( X, Y, Z ) are computer controlled. The back guage adopt ball screw and rolling guideway, ensuring a high accuracy of repetition.

- 5. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

RAYMAX

RX-S Series CNC Press Brake 3-4 Axis

Features

Tags: