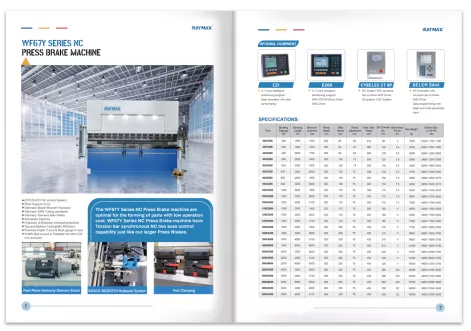

- The hydraulic servo synchronous CNC press brake machine is equipped with an optical grating ruler on the slider and body.

- The CNC system of the bending machine can analyze the synchronization situation on both sides of the slider through real-time feedback information from the optical grating ruler. If there is an error, the CNC system will adjust it through a proportional valve to synchronize the stroke on both sides of the slider.

- The CNC system, hydraulic control valve group, and grating ruler together constitute the feedback closed-loop control of the electro-hydraulic press brake bending machine.

RAYMAX

RX-S Series CNC Press Brake 6 Axis

Features

Tags:

PRODUCT DETAILS

Principle of cnc press brake

The working principle of cnc press brake bending machine mainly includes three parts: hydraulic system, control system and mechanical structure.

Hydraulic system:

Control the movement of machinery by controlling the flow and pressure of liquids.

The hydraulic system includes components such as hydraulic stations, hydraulic cylinders, and related hydraulic pipelines.

Control system:

By programming and controlling the movement and parameter settings of the machine, precise bending of the sheet metal can be achieved.

The control system usually adopts advanced CNC technology, which can accurately control the movement, speed, and force of hydraulic cylinders.

Mechanical structure:

Including components such as the base, upper crossbeam, slider, and workbench.

By the movement of the upper crossbeam and slider, the sheet metal on the workbench can be bent.

Performance of 6+1 cnc press brake machine

- The press brake machine can be configured with various models of dedicated CNC systems: DA66T, DA69T, ESA860, ESA875, etc;

- CNC press brake adopts a brand new rigid design and finite element optimization analysis, it has good rigidity and stability, minimizing the impact of bending deformation on the quality of the workpiece, and ensuring the machining accuracy of the workpiece.

- The hydraulic press brake machine adopts a fully closed-loop electro-hydraulic servo synchronization control system imported from Rexroth, Germany, for feedback synchronization.

- Hydraulic press brake machine adopts a new process design with a minimalist style, the appearance is simple and atmospheric. The machine tool is sandblasted for rust removal, and is also sprayed with anti rust paint.

- Press brake quick clamping structure increase the speed of mold replacement and improve work efficiency. The mold can be installed and removed to the left and right when pull the red handle.

- This 6-axis press brake bending machine, in addition to the conventional Y1 Y2 axis (left and right oil cylinders that drive the slider up and down) The X-axis (forward and backward movement of the backgauge), as well as the R-axis (up and down movement of the backgauge) Z1 axis Z2 axis (left and right movement of finger blocks). The cnc hydraulic press brake machine can be adjusted in four different directions (X, Y, R, Z) is used to achieve bending processing and has balancing control function.

- The press brake machine is equipped with a deflection compensation device, which has functions such as angle compensation, length compensation, and gap error compensation. This device can ensure the accuracy of the processed parts.

CNC Control System