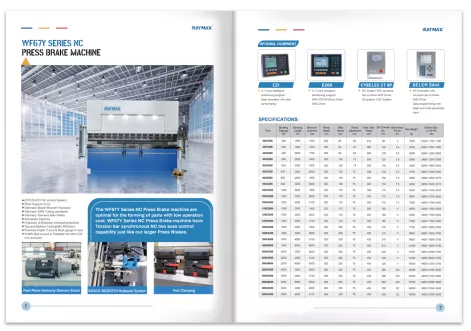

1.Double linkage machine by CNC system can be stand-alone or dual -operating

2.It's standard 2 shafts back gauge system, as to complex shape work pieces, 3 or 4 shafts back gauge system and corresponding dies are available for your option.

3.Press brake using fully closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to CNC system by bilateral gratings, then CNC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider Y1, Y2 running on the same frequency, maintaining the parallel state of the worktable.

4.According to state of sheet metal on the press brake, CNC system can automatically control the table deflection compensation yielding uniform length of all workpieces angles.